CLEANROOM PANELS

Integrated WIP system

Cladding and sandwich panels form a modular WIP system that can be easily integrated with other cleanroom components. The system is based on three basic principles:

Smooth, level surfaces ensure easy removal of dirt.

A minimal number of joints reduces the risk of contamination.

Sealed connections prevent contaminants from escaping.

These principles ensure the creation of cleanrooms that meet the requirements of various industries.

CLEANROOM CEILINGS

In cleanrooms, ceilings must be sealed to prevent contaminated air from the ceiling space from entering the cleanroom. The pressure in clean rooms is usually excessive, so when the doors to the room are opened, a pressure difference occurs, which can lead to the formation of cracks and gaps in the ceiling.

Lamps, laminar flow cells, air distributors and air intake modules can be built into the suspended system of cassette ceilings. The configuration of the ceilings depends on the purpose of the room. For rooms with high requirements for cleanliness, more complex and sealed structures are used.

В подвесную систему кассетных потолков могут быть встроены светильники, ламинарные ячейки, воздухораспределители и воздухозаборные модули. Комплектация потолков зависит от назначения помещения. Для помещений с высокими требованиями к чистоте используются более сложные и герметичные конструкции.

CLEANROOM LIGHTING

Lighting devices in clean rooms must meet special requirements determined by the specific operation of such rooms.

Sealing – Lighting fixtures must be sealed to prevent contaminants from entering the clean room.

Aerodynamic properties – luminaires must be recessed or have the necessary aerodynamic properties so as not to interfere with air circulation.

Serviceability – Lighting fixtures should be easy to maintain so that maintenance personnel can quickly and easily replace lighting elements.

Resistance to cleaning – luminaires must be resistant to cleaning agents and sanitizing preparations.

AIR DISTRIBUTORS FOR CLEANROOMS

KSD is a device that is used to equalize air flow in ventilation systems. Air from the duct enters the chamber, where its speed decreases and the static pressure stabilizes. This allows the air to be evenly distributed throughout the room.

The CSD consists of the following parts:

The body is made of galvanized steel and has a rectangular shape.

Pipe – to connect the camera to the air duct. The diameter of the pipe is specified in the customer’s technical requirements.

The filtration unit is a HEPA filter that removes contaminants from the air.

Grille (diffuser) – distributes air throughout the room.

Lamps, laminar flow cells, air distributors and air intake modules can be built into the suspended system of cassette ceilings. The configuration of the ceilings depends on the purpose of the room. For rooms with high requirements for cleanliness, more complex and sealed structures are used.

CLEANROOM LIGHTING

Air intake modules are devices that provide air intake from a room for its further purification and supply to the room. Modules can be ceiling or wall mounted, that is, air intake grilles can be located both on the ceiling and on the walls.

The main purpose of air intake modules is to ensure the circulation of clean air masses in the room. The modules also protect the ventilation system from the entry of fine dust and debris from the room.

The use of air intake modules must be justified by the technical operating conditions of the clean room. Installation of modules must be carried out in accordance with current building codes and regulations.

VENTILATION AND AIR CONDITIONING SYSTEMS FOR CLEANROOMS

Ventilation and air conditioning systems in clean rooms are designed to provide the following conditions:

Air purity control. The air entering a clean room passes through filters that remove dust particles, microorganisms and other contaminants.

Microclimate stability. The ventilation and air conditioning system maintains constant temperature, humidity and air speed in the room.

Maintain differential pressure. A certain pressure difference must be maintained between clean rooms, which prevents the penetration of contaminated air from one room to another.

Fresh air supply. Fresh air is constantly supplied to clean rooms, which helps create comfortable conditions for people to work and live.

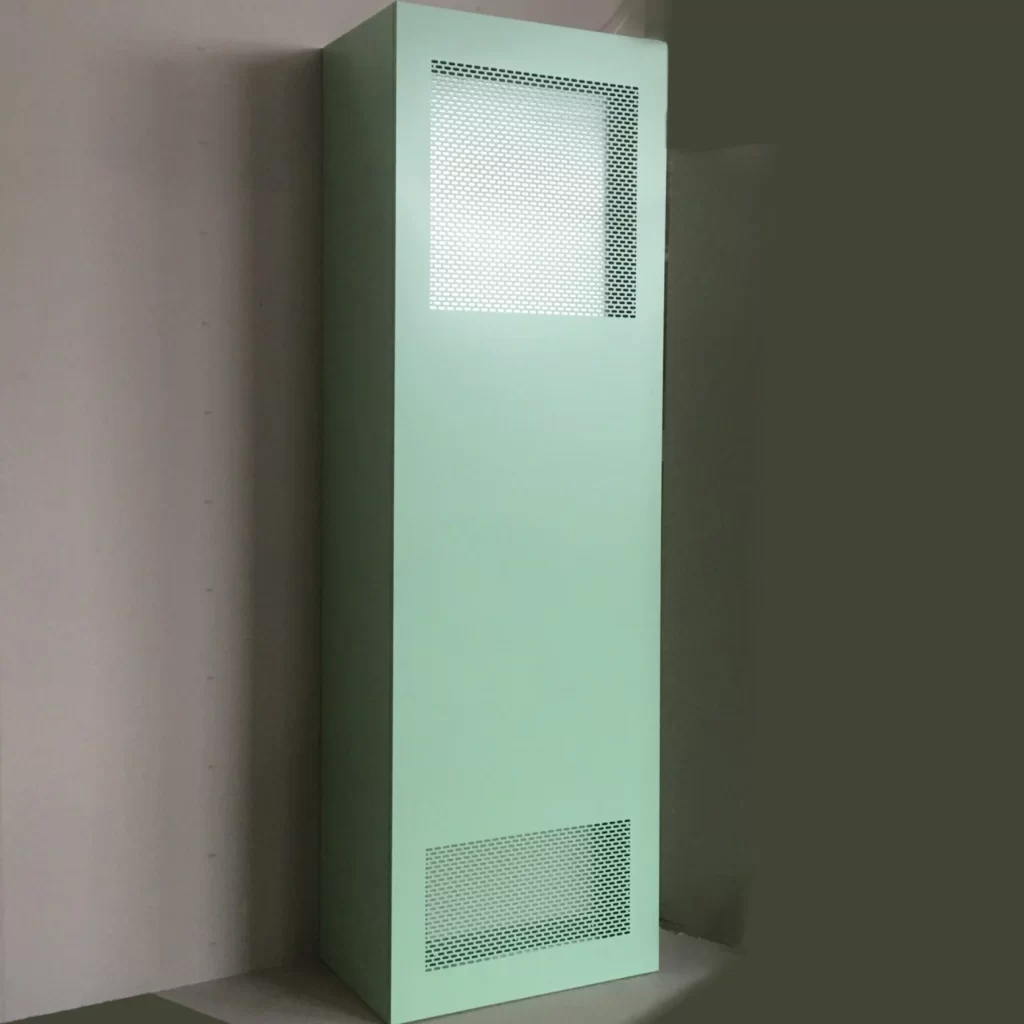

RECIRCULATION COLUMNS

- Ease of operation and maintenance. Filters in the RK are easy to replace, and in some models you can use two filters at the same time, including a fine filter. To remove odors and excess ozone concentration, you can use a carbon filter. The front panel of the RK opens on hinges for easy maintenance, and the filters simply slide in and out. The walls of the RK have a soundproofing layer, which makes them silent.

Saving energy costs. RKs do not require heating or cooling of the supply air, since they use air from the room with the required temperature. The air passes only through RK filters.

LAMINAR SYSTEMS

Laminar flow cells are devices that provide clean, disinfected air into a clean room in the form of a unidirectional flow. The air flow speed in laminar cells cannot exceed 0.3 m/s.

Laminar flow cells are used in the following types of premises:

Resuscitation

Operating

Intensive care wards

Research laboratories

Production facilities for the pharmaceutical, electronics, aviation and space industries

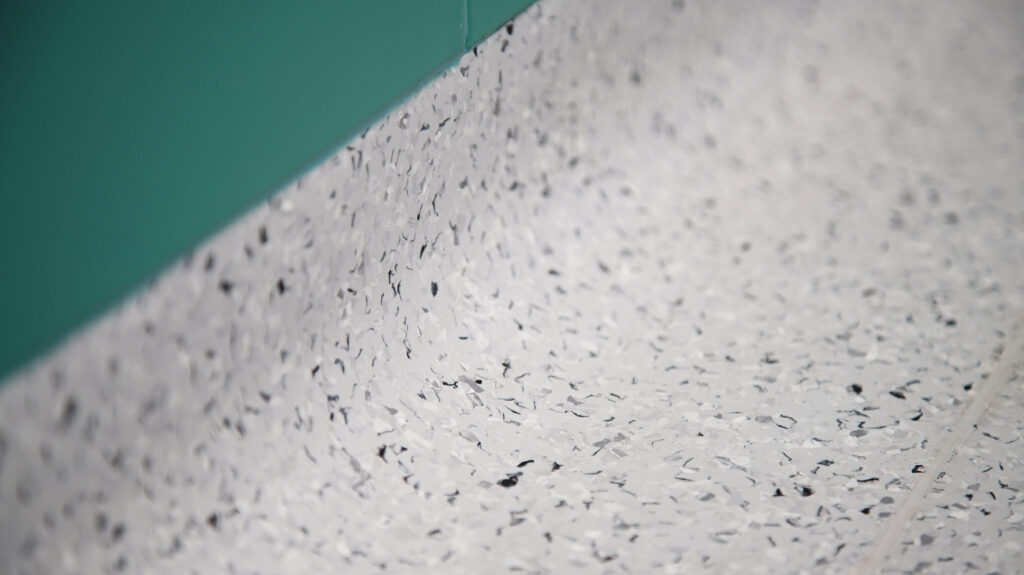

CONDUCTIVE FLOORS AND COATINGS

Conductive floors are used to prevent the build-up of static electricity in areas where computers, precision instruments and medical equipment are operated.

Conductive floors are made from special linoleum, into which carbon threads or a graphite layer are introduced during the production process. These materials allow linoleum to dissipate static charges over its entire surface.

Conductive floors are more expensive than conventional floor coverings due to special technical production conditions.

AUTOMATION FOR SWING AND SLIDING DOORS

Automatic door opening (closing) systems consist of the following main components:

Devices for pressing the door leaf against the opening ensure the tightness of the interior of the room. Most often, special controlled electromagnetic devices are used.

Motion and door lock sensors, security sensors and infrared barriers ensure the safety of the system. Motion sensors are triggered when doors are opened, and door lock sensors, sensors and barriers are triggered when a person is in the doorway.

TRANSFER BOXES

A transfer box is a device that allows you to transfer raw materials and materials from one room to another, while maintaining clean air in both rooms. Boxes come in two-leaf and three-leaf types.

The box doors operate on the airlock principle: when one door is opened, the other doors are blocked, which prevents the mixing of air from different rooms. The box doors, as a rule, are glazed, which allows you to visually monitor the transfer process.

The internal parts of the box are made of stainless steel, which is resistant to corrosion and does not emit harmful substances. External sheets can be made of galvanized steel with a powder coating, which provides protection against corrosion and gives the box an aesthetic appearance.